-

Posts

50 -

Joined

-

Last visited

Content Type

Events

Profiles

Forums

Posts posted by jimbo890

-

-

Nice!

Keep those parts a movin'!

Jim

-

As a last resort, you can use the green limo tint film, and apply that to a clear acrylic sheet or even the comon face shield.

-

Update: 4-April-2007:

Project is still in the works. 90% done on the master pattern. Only minor tweaks, and it's off to the silicone.

Jim

-

WOW Tony!

Those blasters are really looking great!

BTW, you have a PM!

Jim

-

Possible tiny run of these as kits, but still too early to know for sure. Price, will be very affordable, just enough to cover material costs. Availability, not sure yet, but I'll keep everyone updated.

So far it looks like a lightweight option, made from the same resin the govt. uses for dummy training weapons. In black!

-

Well, my new years resolution is to get the Lewis Gun project finished. I've been so busy with other projects, this one just kept getting pused back. No more. I hope to have the prototype sent to Tony for inspection in a few weeks.

Mold masters are now primed, filled and sanded. More details added, and an assembly of the individual parts has been done.

Stay tuned.

Jim

-

I just saw an ad in the Shotgun News, that Catco has some 75 parts kits still available. $500 per kit, but thats about as real as it gets. I thought these were long gone.

FWIW

Jim

-

I really need to get off my butt and get a pack done. Just too darm many projects going on, I can't seem to get all of them done in a timely manner. Soon I hope!

-

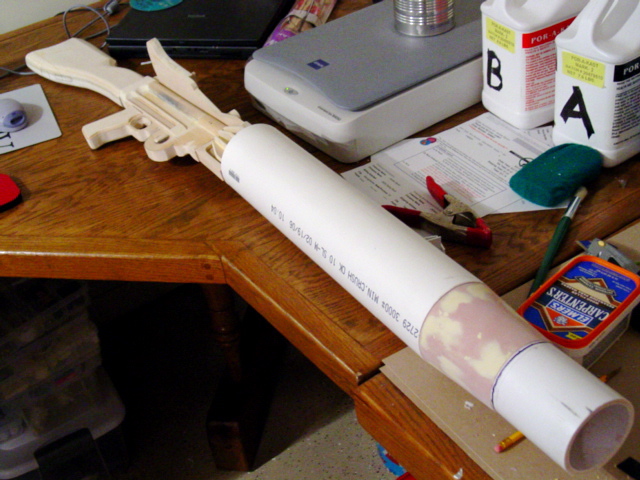

Here are some E-11's I made for a fan film:

and a shot of the 'work in progress' T-21:

-

Deactivated sterlings 4 or 5 years ago were about $300. Long since dried up, and demand has caused the price to go up.

IMA had them and so did cheaper than dirt. Both were 'lumpy'

Jim

-

In the South, there is a product used to repel mosquitos. It comes in a coil, and I think is to be burned like citronella. I've seen guys use this. Me, I'm planning to vacuum form the coil, if I ever get the time .

Jim

-

I use one of those 'multi-bits' The kind that looks like a cone. Works great.

-

What dimensions are you going with on these radio boxes? Width, depth and height?

Jim

off the top of my head, they are 6.5in. wide, by 8.75in. tall.

Deep is not a consideration because it's just the face. The sides need to be built up using sheet plastic. As a vac-former, I think you know how difficult it would be to free a square mold.

Thanks for those dimensions. Yes a square box would be a nightmare, but I am currious, how deep the radio box is suppose to be?

Jim

-

What dimensions are you going with on these radio boxes? Width, depth and height?

Jim

-

I have a Cushman MP43/STG44. As others have stated, pretty soft detail. And fragile from a trooping standpoint. BUT, I filled that thing with resin, and peeled the styrene off, and now have a pretty solid block to carve my own 'Hoth' blaster. I'm sure there are better ways to do this, and I still have the shell that is the MP43/STG44 so in essence I wound up with two.

If you are on a budget, and want a lightweight blaster, and details are not a big issue, this is an option.

I think it's a decent way to get startend on a scratch build. You get the right scale, and basic outline, and you get to add all the details you see fit to add.

IMHO.

-

I really need to get off my butt and make an MG15. Very nice! Well done!

Jim

-

I have the digital version of the Lewis Gun user manual... with a lot of interesting close ups of elements.

Let me know if You're interested.

I can use all the reference material I can get.

Thanks!

Jim

-

That is looking FANTASTIC... you've been busy since you sent me the last update pictures!! That's more or less how I'm going to re-do my barrel too! I assume thats bondo to make the taper?

Thanks for the kind words. I still have some bondo work to do on the receiver, and to make the ejection port and charging handle. Also, some minor stock work needs to be done.

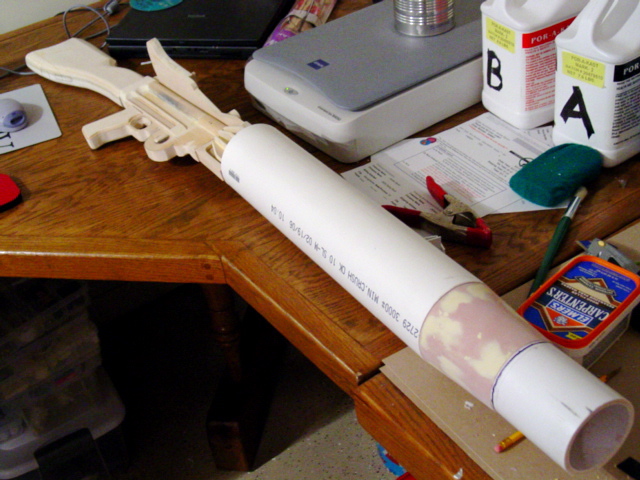

Tony, the barrel taper is indeed made from bondo. But, heres How I did it. I wanted to be able to cast this as a resin part, so I wrapped the smaller pipe with a sheet of printer paper. So that it can slide on the barrel. Then I fitted the larger pipe with an extension coupling the smaller pipe could fit in. Then I mixed up a couple of batches of bondo, and sanded. Once I had the shape I wanted, I cut the bondo loose from the larger pipe, and it slipped off the smaller one. Now I have this donut barrel taper as a separate part.

-

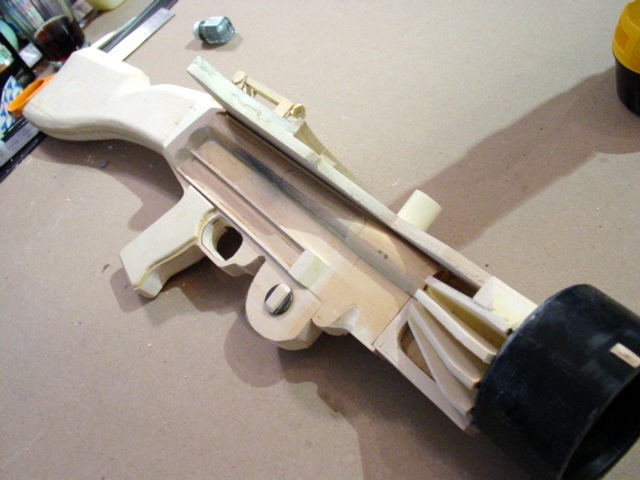

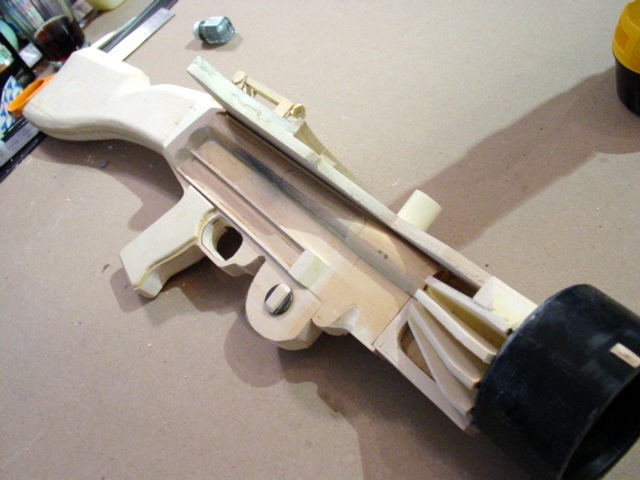

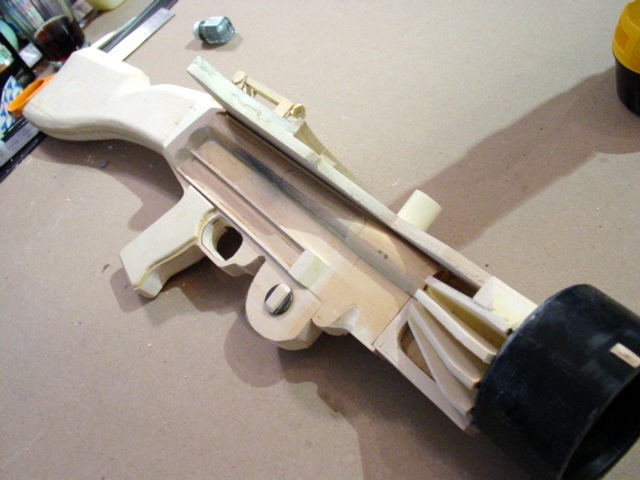

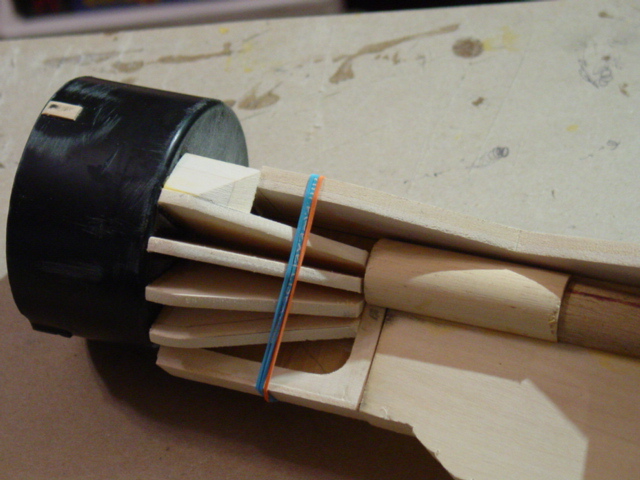

Well, here are some more pics on my Lewis Gun project. These will end up being the master for a resin cast set.

I still have some minor detailing to work out, like the ejection port, charging handle, etc.

The receiver/stock parts.

Almost there.

Barrel donut. Yes, this will be a cast part.

Assembly, still a ways to go!

Stay tuned!

-

Well, here are some more pics on my Lewis Gun project. These will end up being the master for a resin cast set.

I still have some minor detailing to work out, like the ejection port, charging handle, etc.

Stay tuned!

-

These were made for a fan film I'm working on. All are from automotive grade vinyl hand sewn by Heath.

He also made these pauldrons:

and these holsters:

for more info www.tk560.com/catalog.html and for info on the fan film:

-

Resin? Have you looked at Flex-IT foam 5?

Flex-IT foam 5? No. Tell me more?

I'm looking at a resin cast material that Smooth-on sells to make training guns for the FBI. Not hyperfirm as far as I know as that is as much a process as a product.

The goal is to make a few for the film, and friends using these parts cast in this material, and then bolted and glued together with off-the-shelf drain pipe. The taper at the barrel end will also be a custom cast item. The stock will also be cast. The idea came from Tony and his LG that could be broken down for transport, so I'm working on this as a packable option.

I'm not going after a market to sell these, just the ability to make a few for the film project, and the like.

-

HOLY RUSTED METAL BATMAN! That is one fine Lewis! I can't wait to see that baby when it's done. I think that I would be scared to troop with that one...

Thanks for the kind words. It's still early in the construction. The wooden version is a mock-up that I will use as a mold master. The plan is to make some durable resin casts of the parts. The ultimate goal is to have a few made for the fan film I'm working on.

-

Mel!

WoW! Nice Mg34 you have there! I really need to get off my butt and start working on one.

Here is a sneak peek at a project I'm are working on:

A special thanks to Tony for his help on this!

My Completed Butt

in T-21, DLT-19, RT-97c Heavy Blasters

Posted

Well done! Looks the business!